trybeagency

2 Feb 2026

14 Jan 2026

In the fast-moving consumer goods (FMCG) sector, especially within perishable goods like ice cream, inventory management isn’t just about organization, it’s about survival. Every day, products move closer to their expiry dates, and without precise visibility, valuable stock can expire unnoticed, turning potential profit into literal waste.

This was the exact challenge facing Palmary Food, a leading FMCG manufacturer in Algeria, when they launched a new ice cream factory. With a fully new production site and a nationwide cold-chain distribution strategy, Palmary needed a Warehouse Management System (WMS) that could ensure accuracy, traceability, and efficiency from day one.

Enter Trybe Agency, which designed and developed a tailored WMS ecosystem that didn’t just track stock, it transformed how Palmary’s warehouse operated.

Before Trybe’s intervention, Palmary’s warehouse faced a critical lack of visibility. Pallets were stored without real-time tracking of their positions or expiry dates. The First Expire, First Out (FEFO) principle essential for perishable goods was not enforced.

The consequences were stark:

In essence, money was dying in their stock silently and systematically.

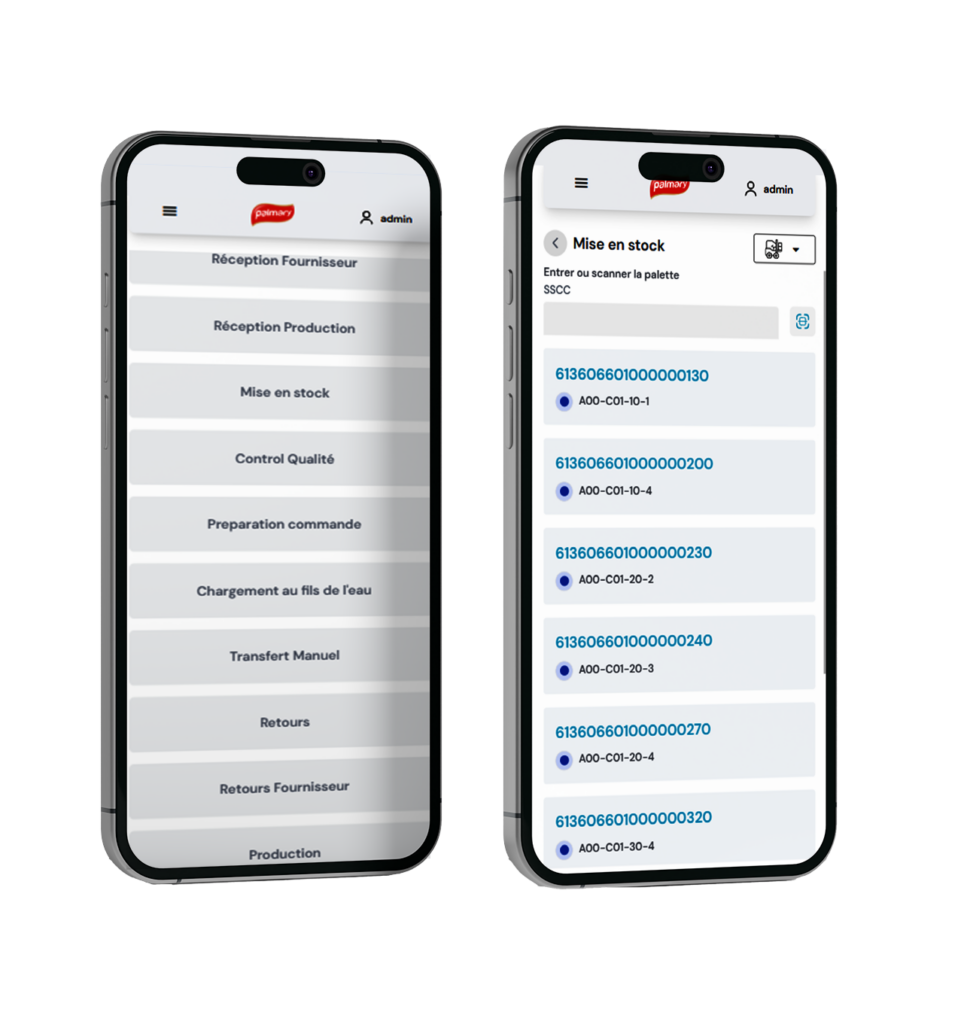

Trybe delivered a comprehensive, modular WMS designed to reflect the real flow of goods from reception to loading while enforcing strict traceability and minimizing human error.

Here’s how the system works across each key warehouse function:

1. Reception & Quality control

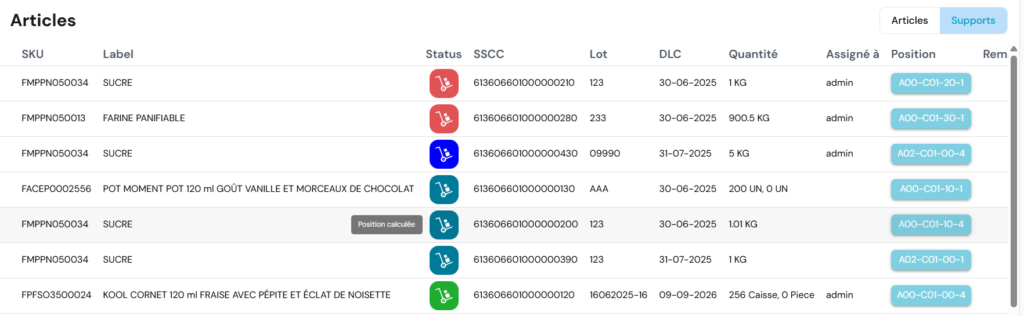

All incoming stock whether from production or suppliers is immediately logged into the system. Each pallet receives a unique SSCC barcode, and operators perform mandatory quality checks. Failed items are automatically routed to blocked zones, while approved pallets move seamlessly into storage.

The system determines the optimal storage location based on ABC classification, FEFO rules, temperature zones, and available space. Operators are guided via mobile app to the exact aisle, rack, level, and position ensuring perfect placement every time.

When orders are prepared, the WMS generates FEFO-optimized picklists, guiding operators through a scanning-first process that eliminates errors and ensures older batches are dispatched first.

Loading is validated in real time. Operators scan each pallet as it enters the truck, and the system alerts them to any mismatches. A final loading sheet confirms what was shipped, by whom, and when closing the logistics loop with full accountability.

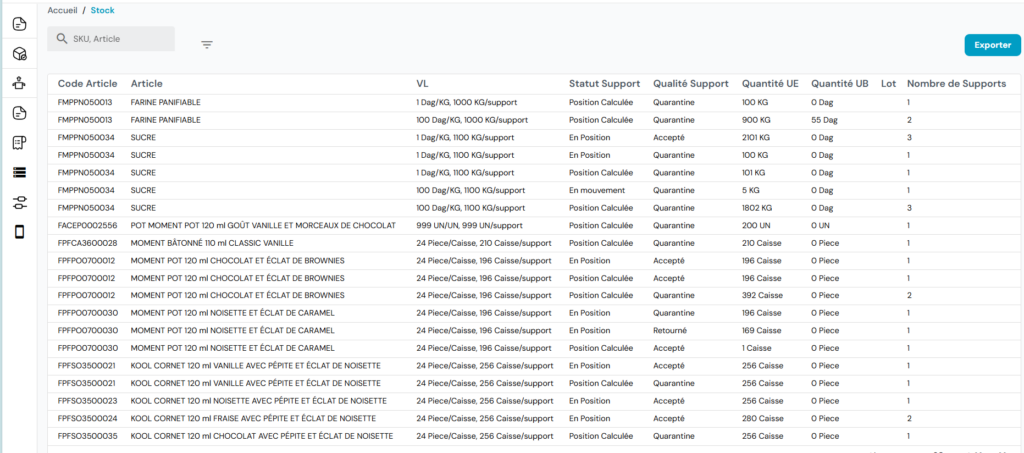

Managers gain real-time dashboards showing stock by zone, aisle, rack, level, and position. Expiry alerts, batch tracking, and movement histories are all visible at a glance, enabling proactive decision-making.

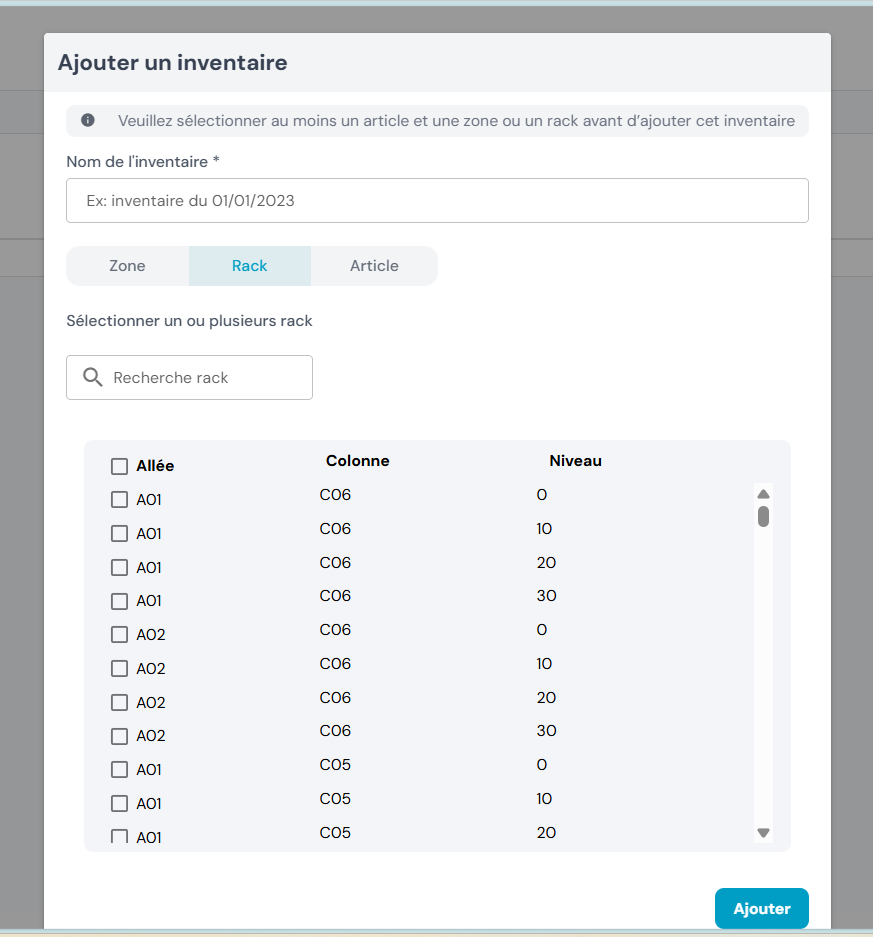

Regular cycle counts are conducted without disrupting operations. The system compares expected vs. actual stock, and managers can validate discrepancies immediately maintaining accuracy without full warehouse shutdowns.

The intuitive mobile app ensures quick adoption, even among seasonal staff. Each task is screen-specific, scanning is mandatory, and feedback is immediate, reducing training time and boosting compliance.

With Trybe’s WMS, Palmary achieved:

Today, Palmary’s warehouse isn’t just a storage space, it’s a data-driven, responsive asset that supports their growth and ensures nothing expires unseen.

881bet

added comment 2 weeks ago

Yo, 881bet, huh? Felt pretty standard to me. Nothing crazy impressive, but nothing that will blow up in your face either if you know what I mean? 881bet

Find guides, articles and infographics to help you improve your business